4

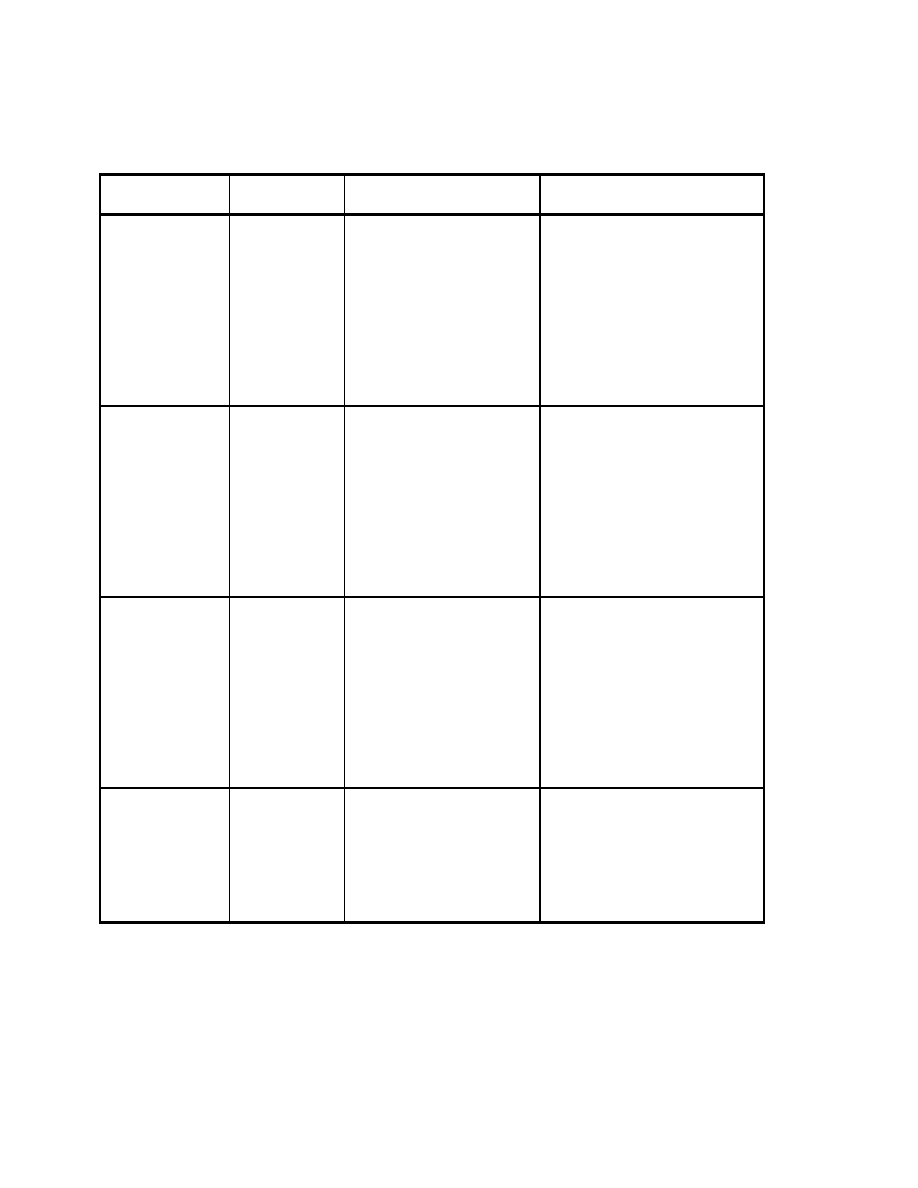

Table 1.

Summary of Technical Targets and Barriers for Reducing

Friction and Wear

Friction and Wear

Challenge

Current

Practice

Practice

Technical Target

Barriers

Cost of

validation

testing

validation

testing

Engine tests

costing

approximately

$60,000 each

costing

approximately

$60,000 each

Inexpensive, predictive

bench-top tests for

cylinder-liner and piston-

ring materials, bearings,

and valve-train

components

bench-top tests for

cylinder-liner and piston-

ring materials, bearings,

and valve-train

components

Lack of quantitative

understanding of failure

modes.

Lack of understanding of time-

dependent in-situ

contamination and degradation

of lubricants.

Lack of model to predict

performance based on material

properties and design features.

understanding of failure

modes.

Lack of understanding of time-

dependent in-situ

contamination and degradation

of lubricants.

Lack of model to predict

performance based on material

properties and design features.

Cost-effective

surface-

modification

technologies

surface-

modification

technologies

Limit

performance

based on bulk-

material

properties

performance

based on bulk-

material

properties

Coatings or other surface

treatments to allow fuel

injectors, pistons, cylinder

liners, and valve-train

components to tolerate

higher stresses, lower

lubricity, and higher

corrosivity resulting from

new emission-reduction

technologies

treatments to allow fuel

injectors, pistons, cylinder

liners, and valve-train

components to tolerate

higher stresses, lower

lubricity, and higher

corrosivity resulting from

new emission-reduction

technologies

High cost of current coatings

and surface-modification

technologies.

Limited wear resistance,

durability, and adhesion.

and surface-modification

technologies.

Limited wear resistance,

durability, and adhesion.

Lubricant and

additive

chemistry

additive

chemistry

Trial-and-

error approach

to lubricant

formulation

error approach

to lubricant

formulation

Develop environmentally

friendly lubricant that is

compatible with new

emission-reduction

technologies

friendly lubricant that is

compatible with new

emission-reduction

technologies

Need model to predict long-

term performance of lubricants

based on properties of base oil

and additives.

Need for sulfur and

phosphorus for high-pressure

applications, but deleterious

effect of sulfur and phosphorus

on catalysts.

Disposal or biodegradability.

term performance of lubricants

based on properties of base oil

and additives.

Need for sulfur and

phosphorus for high-pressure

applications, but deleterious

effect of sulfur and phosphorus

on catalysts.

Disposal or biodegradability.

Comprehensive

computer codes

computer codes

Fragmented

codes unable

to handle

lubricated

parts in

relative

motion

codes unable

to handle

lubricated

parts in

relative

motion

General-purpose

friction/wear/lubrication

codes that include splash

and mist lubrication for

designing low-friction,

low-emission lubricated

components and systems

friction/wear/lubrication

codes that include splash

and mist lubrication for

designing low-friction,

low-emission lubricated

components and systems

Extremely complex system.

Lack of quantitative

understanding of friction and

wear as a function of basic

material properties and loading

conditions.

Lack of quantitative

understanding of friction and

wear as a function of basic

material properties and loading

conditions.

Each team should have expertise in materials, coatings, lubricants, design, and service life

evaluation because all five factors are interrelated and need to be considered to achieve an

optimal solution for most friction and wear problems.

evaluation because all five factors are interrelated and need to be considered to achieve an

optimal solution for most friction and wear problems.

The recommended budget for the first year is $2 million, rapidly increasing to $7 to $10 million

per year for four to five years, supplemented by appropriate industry matching funds. It is

per year for four to five years, supplemented by appropriate industry matching funds. It is