22

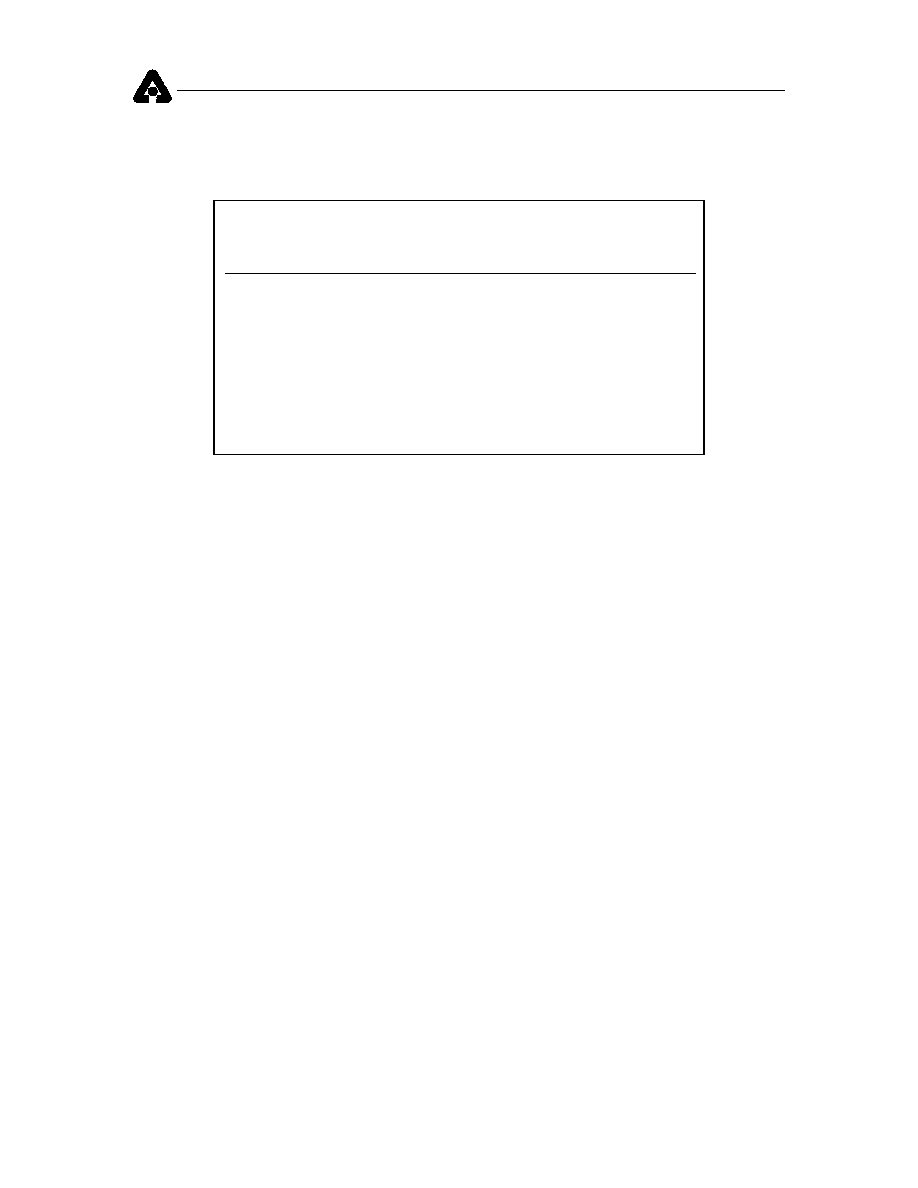

Table 6 Baseline Annual Heating/Cooling Energy Use and CO

2

Emissions for 100% Market Penetration by Alternative

Technologies

Technologies

a

Energy Usage

Petroleum

Technology

(10

12

Btu)

(10

3

gal)

CO

2

Emissions

(10

3

tons)

Truck engine idling

107.5

838,140

9,597

Direct-fired heater plus idle cooling

64.7

504,433

5,764

Direct-fired heater plus thermal

storage cooling

storage cooling

10.2

79,197

907

Auxiliary power unit

19.3

150,860

1,727

Truck stop electrification

34.2

2,127

2,504

a

Assumes 458,000 trucks, with 85 days of heating at 10 h/d and 218 d with average

cooling at 4.5 h/d. Electrification assumes electrified truck stops (hot-bunked) to allow

usage by all trucks.

cooling at 4.5 h/d. Electrification assumes electrified truck stops (hot-bunked) to allow

usage by all trucks.

5.2 Summary

Truck engine idling consumes significant amounts of fuel to provide heating in the winter

and cooling in the summer. Many fuel-efficient options are available to provide heating and

cooling without resorting to idling. Promising options include (1) direct-fired heater for

cab/sleeper heating, with or without storage cooling; (2) auxiliary power units; and (3) truck stop

electrification. Along with truck stop electrification, electricity-based devices in the truck (for

example, those supplied by SCS/Frigette) would be needed. Each option has benefits and

drawbacks.

cooling without resorting to idling. Promising options include (1) direct-fired heater for

cab/sleeper heating, with or without storage cooling; (2) auxiliary power units; and (3) truck stop

electrification. Along with truck stop electrification, electricity-based devices in the truck (for

example, those supplied by SCS/Frigette) would be needed. Each option has benefits and

drawbacks.

The direct-fired heater is very efficient (about 80%, compared with only 11

-

15% for truck

idling) because it simply indirectly heats the air that enters the cab/sleeper area. Net energy

conversion efficiency of electrification (33%) is lower than that of the direct-fired heater, and the

market for electrification is limited to the available spaces, but a complete range of services is

provided. Electrification would most likely be successful over heavily traveled routes, where a

trucker could be sure of finding an electrified stop when he or she needed it. Auxiliary power

units are very efficient and they provide all necessary services at any location. A drawback of

direct-fired heaters is that they do not provide air-conditioning or electric power. Another

drawback is that they need electrical power, and so truckers will be concerned that they will not

have enough battery capacity to restart the engine, especially during cold weather. This option

has had limited market penetration in the past. But direct-fired heaters are small and relatively

inexpensive, and thermoelectric power-conversion devices are under development that promise

to help reduce their electricity consumption.

conversion efficiency of electrification (33%) is lower than that of the direct-fired heater, and the

market for electrification is limited to the available spaces, but a complete range of services is

provided. Electrification would most likely be successful over heavily traveled routes, where a

trucker could be sure of finding an electrified stop when he or she needed it. Auxiliary power

units are very efficient and they provide all necessary services at any location. A drawback of

direct-fired heaters is that they do not provide air-conditioning or electric power. Another

drawback is that they need electrical power, and so truckers will be concerned that they will not

have enough battery capacity to restart the engine, especially during cold weather. This option

has had limited market penetration in the past. But direct-fired heaters are small and relatively

inexpensive, and thermoelectric power-conversion devices are under development that promise

to help reduce their electricity consumption.

If typical trucks average 1,830 h of idling annually, eliminating idling and installing and

operating direct-fired heaters during winter would save about 311 million gallons