|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance WEB™ |

|

Our Web version of EZ

Maintenance™, EZM Web™

is accessible anywhere in the

world there is an internet

connection.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ for Web |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

|

Previous

Section:

Maintenance Schedules for

Equipment Maintenance Schedules for

Equipment |

Next

Section:

Viewing Maintenance Due |

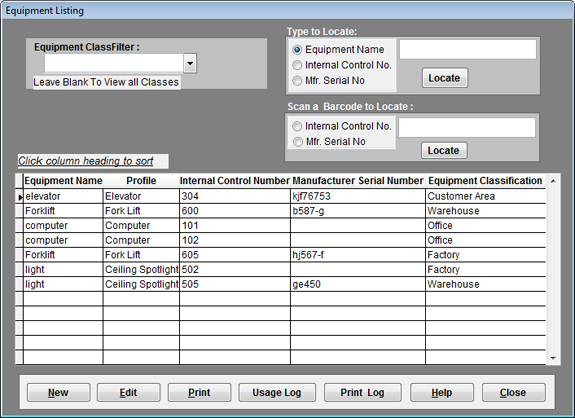

Watch a Video on Viewing and Entering Your Equipment in EZ Maintenance.

Viewing Your Equipment in EZ Maintenance

You can use EZ Maintenance preventive maintenance software to track

maintenance for a virtually unlimited amount of equipment.

At one screen in EZ Maintenance, you can see, at a glance, all of the

equipment that you have entered into EZ Maintenance:

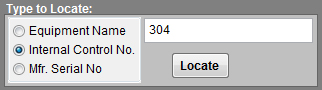

Equipment Search: If the list of equipment you are

tracking is long, you can search for a piece of equipment by entering its

identifying number, its manufacturer's serial number, or the type of

equipment:

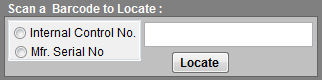

Barcode Search: If you have printed barcoded labels

or stickers for your equipment using EZ Maintenance, you can also search for

a piece of equipment by using a barcode reader to swipe that equipment's

barcode into EZ Maintenance.

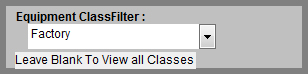

Category Filter: You can also make it so the list of

equipment only displays those belonging to a certain classification; this

means that, for example, you could have the list of equipment display only

those stored at a particular location. You just choose the desired category

from a list and the list of equipment is changed to display only those

belonging to the selected category.

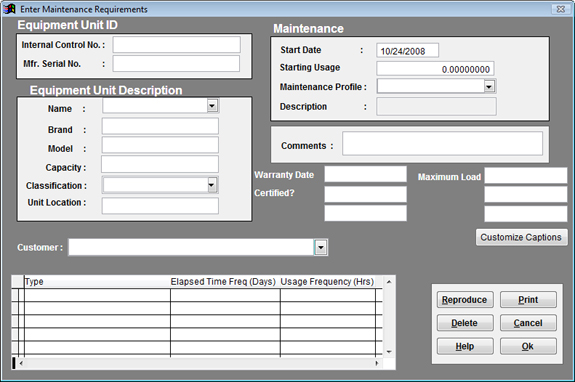

Entering Equipment into EZ Maintenance

Entering new equipment into EZ Maintenance is easy. You simply click on the

New button at the screen where you the list of your equipment (as shown

above) and the following window opens where you enter the information about

the equipment you are entering:

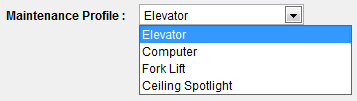

Giving Your New Equipment a Preventive Maintenance

Schedule: To set up a maintenance schedule for your new

equipment, all you have to do is select a maintenance profile from the

Maintenance Profile menu:

Each maintenance profile is an entire maintenance schedule

for some type of equipment. Maintenance profiles, in addition to specifying

the complete maintenance schedule (the maintenance events and the frequency

at which they occur), also include the materials, replacement parts, and

operations that are required in each maintenance event that is scheduled. EZ

Maintenance gives you the ability to create a number of different

maintenance profiles, and each one can contain a maintenance schedule for a

different type of equipment. This implies that it's very easy to set up

maintenance schedules for a large number of equipment, as you don't have to

enter detailed information for the maintenance schedules for each piece of

equipment you're entering; you simply choose the appropriate maintenance

profile.

You must also enter the following information about the new equipment at

this window:

Equipment Unit ID: The Equipment Unit ID is the

unique internal control number you assign to identify the piece of

equipment and the manufacturer's serial number

for it. The internal control number is used to identify the piece of

equipment throughout EZ Maintenance such as in menus and lists.

Equipment Unit Description: Descriptive information

about the piece of equipment: what type of equipment it is,

what brand and model it is, its capacity,

its classification, and where it is

located.

Maintenance: This is some maintenance-related

information for the piece of equipment. The Start Date is

the date on which the equipment's preventive maintenance schedule starts

from. The Starting Usage is the amount of usage (typically

measured in hours) which the equipment already has upon being inputted into

EZ Maintenance. The Maintenance Profile is a complete

description of the maintenance schedule for the piece of

equipment.

Customer: If you are servicing the equipment for an

outside customer, you can choose that customer from this menu.

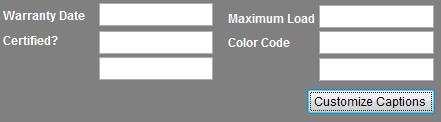

Custom Fields: EZ Maintenance also gives you six

custom fields that have names which you can specify:

Reproducing a Piece of Equipment

You can also create a new piece of equipment in EZ Maintenance exactly like

an existing one. This is called Reproducing a piece of equipment. This

creates a new piece of equipment exactly like an existing one, although you

have to choose a new internal control number for the new

equipment.

This is done using the Reproduce button:

|

Previous

Section:

Maintenance Schedules for

Equipment Maintenance Schedules for

Equipment |

Next

Section:

Viewing Maintenance Due |

|

|

|

| 1. |

How do we schedule maintenance and service? Do we have to type in each service date? |

| |

No. You simply enter the preventive maintenance or service to be performed, and then enter the cycle; i.e. every day, every week, every month, etc. EZ Maintenance fleet maintenance software will automatically schedule the preventive maintenance or service on an on going basis from the day you schedule the first maintenance on the cycle you have selected. In other words, if you, for example, have a preventive maintenance or service you want to have take place once each week, when you enter the work you want done weekly, EZ Maintenance fleet maintenance software will automatically schedule that preventive maintenance to take place weekly thereafter. |

|

|

|

|

|

|