|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance WEB™ |

|

Our Web version of EZ

Maintenance™, EZM Web™

is accessible anywhere in the

world there is an internet

connection.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ for Web |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

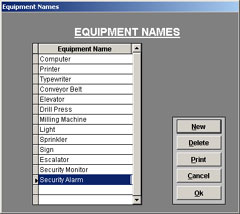

| Equipment Setup

Details |

Equipment

Names allow you to quickly sort and find equipment by

category. First, enter general Equipment Name categories.

Then enter specific equipment items under the general

category. For example, a general category Equipment Name

could be "Computer"; then, each and every individual

computer will be entered & listed under the general

"Computer" category. Equipment

Names allow you to quickly sort and find equipment by

category. First, enter general Equipment Name categories.

Then enter specific equipment items under the general

category. For example, a general category Equipment Name

could be "Computer"; then, each and every individual

computer will be entered & listed under the general

"Computer" category.

|

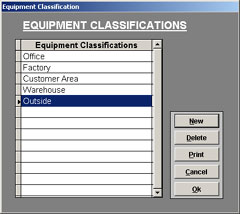

Equipment

Classification allows you to quickly sort and find equipment

by physical location. For example, your company may have

a main office, a factory, and a storage location or have

equipment located at various client site locals. You can

list outside customers by individual company names, i.e.

"Joe's Corporation", to sort and locate all

equipment at his specific company. Equipment

Classification allows you to quickly sort and find equipment

by physical location. For example, your company may have

a main office, a factory, and a storage location or have

equipment located at various client site locals. You can

list outside customers by individual company names, i.e.

"Joe's Corporation", to sort and locate all

equipment at his specific company.

|

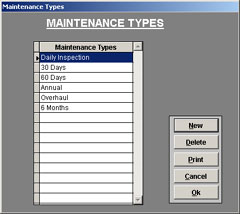

Maintenance

Types lists time intervals when maintenance is to be performed

on equipment. These types will be as varied as your needs

from daily inspections, to 30-day maintenance to Overhaul

and so forth. The Maintenance Types are used when scheduling

maintenance for particular equipment pieces and when creating

Work Orders. Maintenance

Types lists time intervals when maintenance is to be performed

on equipment. These types will be as varied as your needs

from daily inspections, to 30-day maintenance to Overhaul

and so forth. The Maintenance Types are used when scheduling

maintenance for particular equipment pieces and when creating

Work Orders.

|

Materials

data setup is a comprehensive list of the various parts

actually used in maintaining the equipment. Materials

could include belts, bearings, bulbs; you name it. The

data fields allow for entering specific Material Numbers

along with short descriptions. Later, the entered Materials

will appear on future drop down menus. Materials

data setup is a comprehensive list of the various parts

actually used in maintaining the equipment. Materials

could include belts, bearings, bulbs; you name it. The

data fields allow for entering specific Material Numbers

along with short descriptions. Later, the entered Materials

will appear on future drop down menus.

|

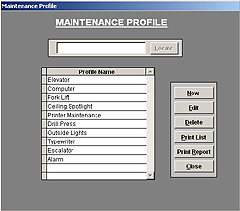

A

Maintenance Profile provides an exact description of the

scheduled, preventative maintenance for each piece of

equipment, essentially detailing the when, what and how

needed to maintain that piece of equipment. A particular

piece of equipment will have multiple and recurring maintenance

events, (i.e.: daily, weekly, monthly, etc.) in the course

of a year. Each event must be described in detail listing

all the Operations and specific Materials, etc. required

to perform the maintenance. Doing this over and over again

for each piece of similar equipment, (same make and model,

for example) is time-consuming and involved, but not so,

using EZ Maintenance. Once a Maintenance Profile is created

for a particular type or model of equipment, it can be

quickly & easily used for each additional piece of

equipment, which is of the same type & model. For

example, after the Maintenance Profile is created for

a particular kind of equipment, say a "37-B drill

press"; then when the next "37-B drill press"

is entered, all the user needs to do is simply select

the Maintenance Profile for a "37-B drill press"

from the drop down menu, and EZ Maintenance will set up

and schedule the exact same recurring maintenance schedule

with all details for the second "37-B drill press"

(and every other "37-B drill press" entered,

thereafter). The Maintenance Profile is a key element

of EZ Maintenance, as it is a valuable time & trouble

saving feature. In summary, by first creating and entering

a Maintenance Profile for a specific equipment piece and

then selecting that profile from the drop down list when

entering new pieces of equipment of the same type, all

maintenance events will automatically be set up for the

new equipment entered and maintenance scheduling will

begin from the date each piece of new equipment is entered

forward. A

Maintenance Profile provides an exact description of the

scheduled, preventative maintenance for each piece of

equipment, essentially detailing the when, what and how

needed to maintain that piece of equipment. A particular

piece of equipment will have multiple and recurring maintenance

events, (i.e.: daily, weekly, monthly, etc.) in the course

of a year. Each event must be described in detail listing

all the Operations and specific Materials, etc. required

to perform the maintenance. Doing this over and over again

for each piece of similar equipment, (same make and model,

for example) is time-consuming and involved, but not so,

using EZ Maintenance. Once a Maintenance Profile is created

for a particular type or model of equipment, it can be

quickly & easily used for each additional piece of

equipment, which is of the same type & model. For

example, after the Maintenance Profile is created for

a particular kind of equipment, say a "37-B drill

press"; then when the next "37-B drill press"

is entered, all the user needs to do is simply select

the Maintenance Profile for a "37-B drill press"

from the drop down menu, and EZ Maintenance will set up

and schedule the exact same recurring maintenance schedule

with all details for the second "37-B drill press"

(and every other "37-B drill press" entered,

thereafter). The Maintenance Profile is a key element

of EZ Maintenance, as it is a valuable time & trouble

saving feature. In summary, by first creating and entering

a Maintenance Profile for a specific equipment piece and

then selecting that profile from the drop down list when

entering new pieces of equipment of the same type, all

maintenance events will automatically be set up for the

new equipment entered and maintenance scheduling will

begin from the date each piece of new equipment is entered

forward.

|

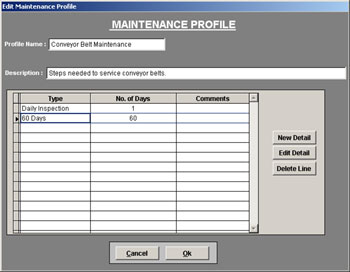

To

create a new Maintenance Profile, click New. (For demonstration

purposes, the screen you see here has data previously

entered). Begin by choosing the Profile Name and then

describe it in detail in the Description area. This 'snapshot'

screen lists all maintenance, (including recurring), that

needs to take place, the number of days in between each

maintenance, and finally when the maintenance is due.

Later when maintenance is due, EZ Maintenance will alert

you with a 'pop up' on the Maintenance Due screen; when

completed, it automatically reschedules itself! To

create a new Maintenance Profile, click New. (For demonstration

purposes, the screen you see here has data previously

entered). Begin by choosing the Profile Name and then

describe it in detail in the Description area. This 'snapshot'

screen lists all maintenance, (including recurring), that

needs to take place, the number of days in between each

maintenance, and finally when the maintenance is due.

Later when maintenance is due, EZ Maintenance will alert

you with a 'pop up' on the Maintenance Due screen; when

completed, it automatically reschedules itself!

|

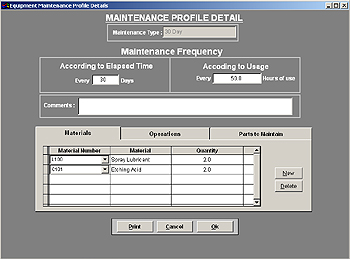

Next

click New Detail to continue creating the new Maintenance

Profile. The three sections Materials, Operations and Parts to Maintain

shown

as tabs on the lower screen, contain the remaining data

areas to complete. The Materials tab allows you to choose,

from a drop-down list, the Materials that have been previously

entered into the Materials portion of the SETUP menu.

The Material part Number, Name and actual Quantity required

to perform that specific type of maintenance is listed. Next

click New Detail to continue creating the new Maintenance

Profile. The three sections Materials, Operations and Parts to Maintain

shown

as tabs on the lower screen, contain the remaining data

areas to complete. The Materials tab allows you to choose,

from a drop-down list, the Materials that have been previously

entered into the Materials portion of the SETUP menu.

The Material part Number, Name and actual Quantity required

to perform that specific type of maintenance is listed.The Operations tab

similarly allows choice from previously

entered Operations by using a drop-down menu and lists

all Operations in sequence. When the Memo field of an

Operation is double-clicked, the exact instructions

that will be printed out on a future Work Order can

be viewed. Lastly, the Materials can be printed as a

pick list and the Operations printed on a Work Order

in a step-by-step detailed process specifying what's

required to complete the job.

The Parts tab allows you to select specific parts of an individual piece

of equipment which need their own maintenance at period intervals.

|

|

|

|

|