|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EZ Maintenance WEB™ |

|

Our Web version of EZ

Maintenance™, EZM Web™

is accessible anywhere in the

world there is an internet

connection.

|

| |

|

| Partial Client List |

|

| EZ Maintenance™ for Windows

|

| EZ Maintenance™ for Web |

| |

|

|

|

| Features |

|

- Schedule All Maintenance

- Equipment & Vehicles

- Full Inventory Control

- P.O.s, RFBs, Invoices

- Work Orders, Bar Coding

- Emergency Work Orders

- Email Alerts

- QuickBooks Link

- Send Work To Vendors

- Customer/Vendor Tracking

- Track Customers

- Maintenance Histories

- Access Passwords

- Supervisory Control

- And Much More!

|

|

| Contact Information |

|

Pinacia Inc.

5699 Kanan Road, #349

Agoura Hills, CA USA 91301

Phone: (818) 396-8550

Sales Support: ext. 1

Tech Support: ext. 2

Fax: (818) 396-3524

info@pinacia.com

|

|

|

|

|

|

Next

Section:

Entering

and Viewing Equipment

|

Click here to see details

on Equipment Setup

Click here to see a video on Maintenance Schedules for Equipment.

|

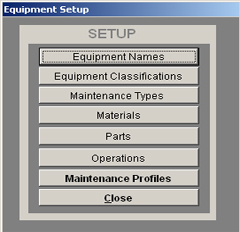

| Setting up

EZ Maintenance CMMS |

In

order for the Equipment Maintenance module to function,

basic information must be entered. The SETUP

menu is where entering basic data takes place. Once entered,

the information will never need to be entered again. This

one time entry makes data available throughout the program

to schedule preventive maintenance, create Work Orders, produce reports,

etc. You can either enter all data at one time or enter

the various data, as you develop Work Orders and preventive maintenance

requirements. Entering all at once or as you go makes

no difference to the functionality of EZ Maintenance CMMS preventative

maintenance software. In

order for the Equipment Maintenance module to function,

basic information must be entered. The SETUP

menu is where entering basic data takes place. Once entered,

the information will never need to be entered again. This

one time entry makes data available throughout the program

to schedule preventive maintenance, create Work Orders, produce reports,

etc. You can either enter all data at one time or enter

the various data, as you develop Work Orders and preventive maintenance

requirements. Entering all at once or as you go makes

no difference to the functionality of EZ Maintenance CMMS preventative

maintenance software.

|

Enter

data into the SETUP menu as follows: Enter

data into the SETUP menu as follows:

Equipment Names allow you

to quickly sort and find equipment by category.

Equipment Classifications

allows you to quickly sort and find equipment by physical

location.

Maintenance Types

lists time intervals when preventive maintenance is to be performed

on equipment.

Materials data is

a comprehensive list of the various parts actually used

in maintaining the equipment.

Parts is a section

that is designed to allow you to schedule maintenance that

may be required on your equipments individual parts, such as a transmission.

Operations list the

complete description, the actual 'how-to', in performing

each specific preventive maintenance.

Maintenance Profile

provides an exact description of the scheduled, preventative

maintenance for each piece of equipment, essentially detailing

the when (Maintenance Types), what (Materials), and how

(Operations). By first creating and entering a Maintenance

Profile for a specific equipment piece and then selecting

that Profile from the drop down list when entering new

pieces of equipment of the same type, all preventive maintenance

events will automatically be set up for the new equipment

entered and preventive maintenance management and scheduling will begin from

that

date forward.

|

Some closing

SETUP notes:

For maintenance management and quality-control purposes, data, (Equipment

Names, Classifications, Maintenance Types, Materials,

Operations and so forth), can only be entered from the

main SETUP menu. To ensure consistency throughout the

program, the data cannot be entered 'on the fly' by maintenance

staff or workers handling the job or creating a Work Order.

To guarantee the information being used throughout the

program is reliable, data can only be entered in SETUP

with a management or middle-level password.

The Equipment Maintenance Module contains numerous reports

ranging from Work Orders to Maintenance Histories, etc.

These reports can be viewed or printed from the section

of the EZ Maintenance CMMS tour that coincides with the particular

report purpose or from the main index of reports. The

Report Index is available for review by clicking

here. |

Next

Section:

Entering

and Viewing Equipment

|

|

|

|

| 1. |

If we enter a maintenance/service procedure once, can we use that procedure on another piece of equipment or vehicle without having to re enter it? |

| |

Yes, of course. Once you have entered a specific maintenance/service procedure, you can specify the use of that procedure on any other piece of equipment or vehicle by simply clicking on it on a drop down menu. |

| 2. |

Can we enter both detailed instructions on how the scheduled maintenance or service is to be performed and the parts and materials required? |

| |

Yes, and a work order can be printed listing all procedures and parts/materials.

|

| 3. |

If we enter a maintenance/service procedure once, can we use that procedure on another piece of equipment or vehicle without having to reenter it? |

| |

Yes, of course. Once you have entered a specific maintenance/ service procedure, you can specify the use of that procedure on any other piece of equipment or vehicle by simply selecting it on a drop down menu. |

| 4. |

If I forgot to enter something in setup, do I need to go back to setup? |

| |

If find yourself in the situation that you forgot to enter enough information while setting up EZ Maintenance, that's alright because the program was designed to a re-build as you setup. This means that at any time an operator with a supervisor clearance can enter new information into the system to better keep track of your equipment and vehicles. |

| 5. |

Can I organize material names/numbers in alpha or numeric sequences? |

| |

Yes, EZ Maintenance allows you to organize any table by clicking on the header to organize by that column. |

| 6. |

Do I need to enter every service or material I'll ever use? |

| |

No, EZ Maintenance allows users to build as they go, or input information as needed. If you find yourself in the situation that you forgot to enter enough information while setting up EZ Maintenance, that's alright because of the program's design as you go setup an operator with a supervisor clearance or above can enter new information into the system to better keep track of your equipment and vehicles. |

|

|

|

|

|

|